How to Get Steadier Flow Using Pulsation Dampeners

March 28, 2023

Fluid flow systems are integral to many industrial processes, including chemical processing, water treatment, and oil and gas pipelines. However, fluctuations in flow rates can cause a range of issues, from equipment damage to inconsistent product quality.

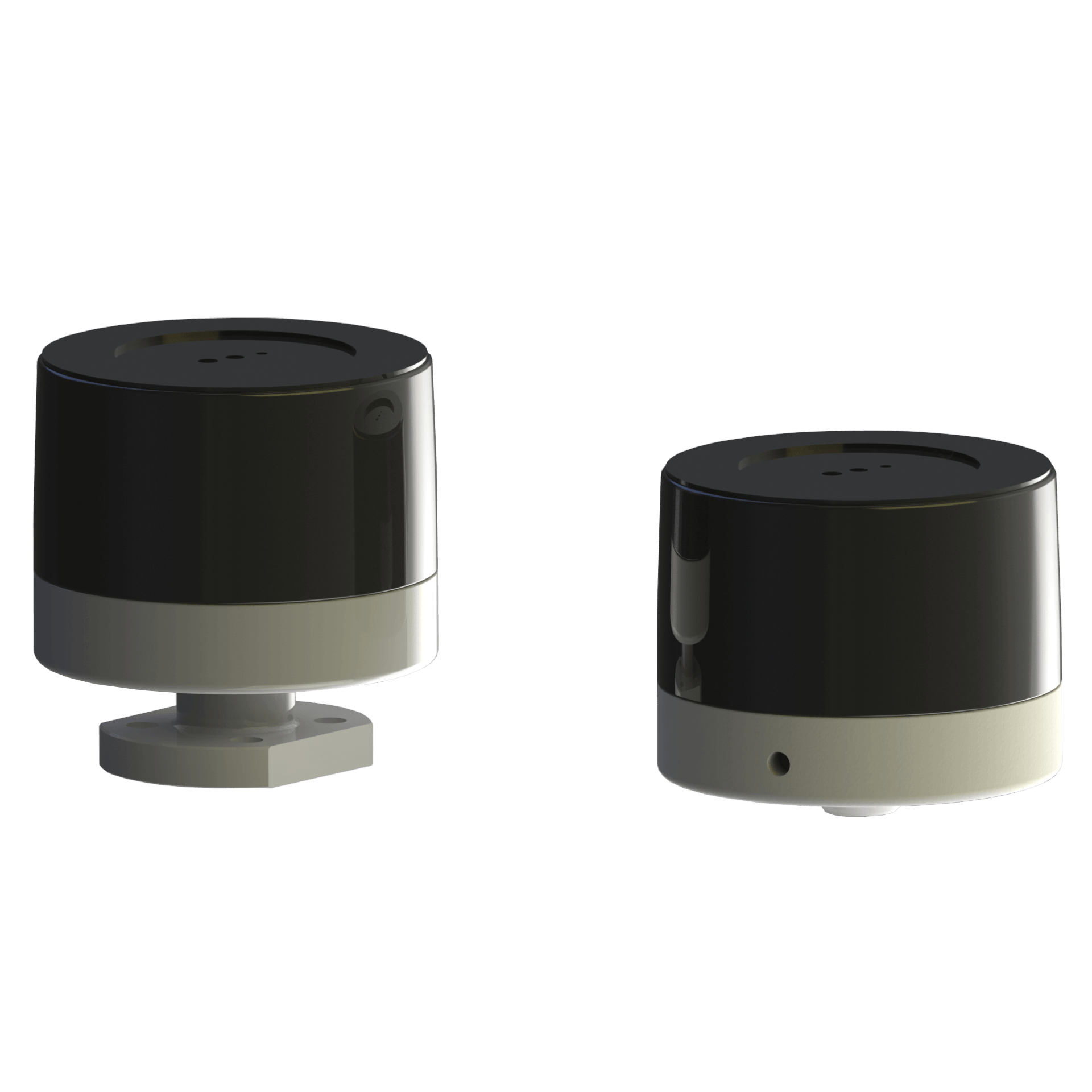

One effective solution to these issues is the use of pulsation dampeners. Pulsation dampeners work by reducing pulsations and pressure surges in fluid flow systems, creating a steadier flow and improving the overall performance of the system.

What is a Pulsation Dampener?

A pulsation dampener is also known as a pressure pulse dampener. These devices are commonly used in chemical processing, water treatment, and oil and gas pipelines.

Pulsation dampeners work by absorbing pressure fluctuations and smoothing out the flow of fluid in a system. They achieve this by using a flexible bladder that acts as a barrier between the fluid and the pipeline.

When pressure surges occur, the bladder expands, storing the excess fluid and reducing the pulsations in the system. When the pressure drops, the bladder contracts, releasing the stored fluid into the pipeline and maintaining a steady flow.

Signs a Flow System Needs a Pulsation Dampener

Several signs indicate that you may need a pulsation dampener in your fluid flow system. Here are some of the most common signs and why they should not be ignored.

● Fluctuations in flow rate.

Pulsations and pressure surges can cause flow rates to fluctuate, which can lead to inconsistent production or processing.

● Vibrations and noise.

Pressure fluctuations can cause vibrations and noise, which can be a nuisance to operators and can even cause damage to nearby equipment.

● Premature wear on equipment.

Pressure fluctuations can cause equipment to wear out more quickly, which can lead to increased maintenance costs and downtime.

● Leaks.

Pressure surges and pulsations can cause stress on the pipes and fittings, leading to leaks and frequent repairs.

● Inconsistent product quality.

Pulsations and pressure surges can cause variations in product quality, which can be costly and potentially dangerous depending on the application.

If you notice any of these signs in your fluid flow system, a pulsation dampener can help to reduce pressure surges and pulsations. This will create a steadier flow and improve the overall performance of the system.

How to Get Steadier Flow Using Pulsation Dampeners

Pulsation dampeners are not a “one size fits all” fix. To get the best results, there are several things to take into consideration. Here are the steps to adding pulsation dampeners to your flow system.

1. Determine How Many Dampeners You Will Need

Some systems might need a single pulsation dampener, while others might need multiple ones to deal with the fluctuations in flow.

2. Determine the Right Size for Each Area

The size of the pulsation dampener required depends on the flow rate, pressure, and the type of fluid being transported. It is important to ensure that the pulsation dampener you choose is the correct size for your specific application. If the dampener is too small, it won't be effective in reducing the pulsations in the system. If it's too large, it will be costly and may cause more problems.

3. Install the Pulsation Dampener

The pulsation dampener should be installed near the pump or in the pipeline to ensure that it is effective in reducing the pulsations in the system. The installation process may vary depending on the type of dampener and the specific application.

4. Adjust the Pressure Settings

The pressure settings should be adjusted to match the pressure and flow rate of the system. This will help to ensure that the dampener reduces the pulsations and creates a steadier flow.

5. Monitor and Maintain the System

This can be done by measuring the pressure and flow rate before and after the pulsation dampener. If the dampener is not working correctly, adjustments may need to be made to the pressure settings or the size of the dampener.

Regular maintenance is essential to ensure that the pulsation dampener is functioning correctly. This can include checking for leaks, replacing worn parts, and cleaning the system. Proper maintenance will help to extend the lifespan of the pulsation dampener and ensure that it continues to work effectively.

Sparkling Clear Industries Can Help With Your Flow System Needs

Do you have questions about your pulsation dampener or other parts of your flow system? Our mission is to do right by you and to meet your needs fast and efficiently. Contact us to talk to one of our experts about ways to improve your flow system today.

Share this Post!

Sparkling Clear Industries is proud to take part in the 2026 DOW Winter Classic Golf Tournament , a full-day charity event benefiting United Way Galveston County Mainland. The tournament will be held Thursday, February 26, 2026, at Bayou Golf Course in Texas City, bringing together industry professionals for friendly competition, networking, and community support. Hole assignments will be announced soon—stay tuned for details on where to find us on the course. The event features a shotgun 4-man scramble format with both morning and afternoon flights, beginning with check-in at 6:30 a.m. and tee times starting at 7:30 a.m. As a sponsor, Sparkling Clear Industries will host a hole and serve food from our Green Monster cook trailer throughout the day. If you’re attending, we invite you to stop by, grab a bite, and connect with our team while supporting a great cause. We look forward to seeing you on the course!

Sparkling Clear Industries is heading to the HASC Tailgate Extravaganza, and we’re looking forward to connecting with industry peers at one of the region’s most anticipated safety-focused events! 📅 Friday, February 6, 2026 🕛 Booths open at 11 AM 📍 Pasadena Fairgrounds The 2026 Tailgate theme, The Golden Age of Safety, is a fitting one. It’s a nod to an era defined by craftsmanship, reliability, and pride in doing things the right way—values that still matter today, especially in industrial environments where safety and uptime go hand in hand. If you’re attending the Tailgate, we invite you to stop by Booth 316. We’ll be happy to talk industrial filtration , reliability, and safety—and grab a steak popper or street taco while you’re there! 🌮 Registration to attend is not required. This free event is open to industry, so bring your colleagues for a day of celebration, safety, and fun! Discover more information here: https://www.hasc.com/tailgate/